What Is Custom Metal Fabrication?

by siteadmin

What Is Custom Metal Fabrication?

Whether it's a set of decorative wrought iron gates or a bespoke stainless steel machinery part, custom fabrication takes the shape of making something that isn't available off the shelf. Some fabricators specialize in a broad technology mix that includes not only cutting, bending and welding but also machining, stamping, and assembly.

Sheet Metal Fabrication

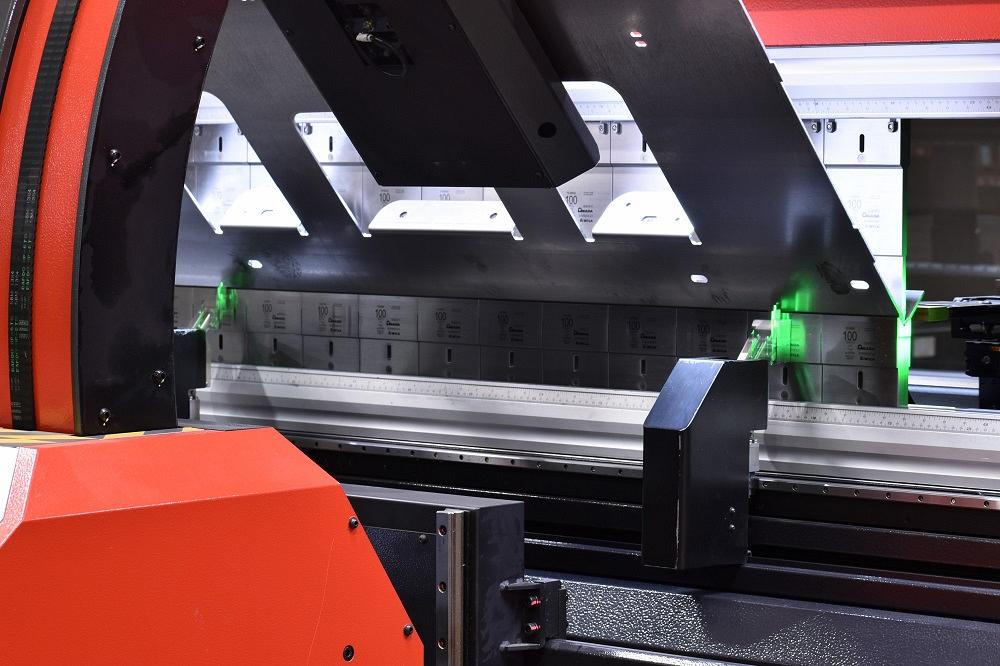

You likely encounter sheet metal products in your daily life at home, work, or play. Sheet metal is a versatile and durable material that can be used to create a wide variety of different products and components. Sheet metal fabrication involves using different tools to cut and shape thin sheets of metal into new designs. These tools include shears that can make straight cuts; bending machines, which can bend metal into any number of shapes; punches that can create holes; and grinding and sanding equipment to smooth out edges.

Other metal fabrication processes include drawing and deep drawing, which transform flat sheet metal into three-dimensional shapes, and flanging, in which manufacturers bend the metal along a curved line. Other important factors in sheet metal fabrication include maintaining consistent bend radii, avoiding holes and slots in the grain structure, and making sure that collars and lugs are not parallel to pierce areas. These factors can help to prevent cracks in the final product.

Metal Fabrication Processes

Metal fabrication has been around for a long time, evolving from the work of blacksmiths and hammers to sophisticated machinery and technology. Fabrication processes vary, but a few of the most common include shearing (cutting metal along a line), stamping (placed between two dies that hammer on the sheet with a high force), and bending. Other processes like extrusion (passing a metal piece through a pair of dies to create a final product with smaller cross-sectional area) and machining are also utilized.

Commercial fabricated metals are used in many of the products you see everyday, whether it’s a decorative wrought iron fence or the stainless steel machinery that makes your car run. They are generally more functional than structural, as the pieces may need to be lighter for transportation or storage purposes.

Some fabricators choose to specialize in specific areas but the vast majority offer a broad technology mix. This allows them to serve customers by reviewing custom project designs for manufacturability and providing them with a quote for the work required.

Metal Fabrication Materials

Metal fabrication uses a wide range of materials to bring ideas to life, from the standard off-the-shelf metals used for generic products to unique metals for specific purposes. Stainless steel, for example, is commonly used because of its corrosion resistance and other physical properties, while copper is a popular choice for applications that require electrical conductivity.

Shearing, bending, and stamping are common metal fabrication processes. Shearing cuts metal along a straight line, while bending uses a machine that applies pressure to a flat sheet of metal to mold it into a particular shape. Stamping involves placing a sheet of metal between two dies that hammer on it with force.

When choosing a metal fabricator, look for a company that handles all steps of the process in-house. This will save time and ensure the quality of the final product. Also, ask if the company provides any additional services, such as assembly or finishing techniques like grinding and powder coating.

Metal Fabrication Applications

Metal fabrication can be used for a variety of purposes. Some types of metal fabrication are especially useful for creating components for machines, tools and other equipment. Others are used to create decorative or structural elements for buildings, spaces and other structures.

Some of the most common metal fabrication processes include cutting, stamping, bending and welding. Many of these processes require raw materials that are thin enough to assume the desired shape. This may mean starting with a sheet of flat metal or working with already-formed pieces like bars or measured panels.

For example, metal fabrication can help create parts for machine tools, allowing manufacturers to produce specialized machinery with unique designs and features. Metal fabrication can also be used to produce a wide range of hardware products, from the enclosures on hard drives to the metals used in computer monitors and other components. It is also responsible for the sharpness of cutlery and the precision of hand tools.

Metal Fabricator

What Is Custom Metal Fabrication? Whether it's a set of decorative wrought iron gates or a bespoke stainless steel machinery part, custom fabrication takes the shape of making something that isn't available off the shelf. Some fabricators specialize in a broad technology mix that includes not only cutting, bending and welding but also machining, stamping,…

Recent Posts

- Kings Commercial Roofing LLC Elevates the Standard of Roofing Solutions in Missoula, MT

- Ripple Effect Culture Revolutionizes Leadership Development and Talent Management Consultancy

- Garage Builders Seattle: Revolutionizing Custom Garage Construction in Seattle

- Pro Mold Cleanup Roseville: Leading the Way in Professional Mold Removal

- Pro Mold Cleanup Roseville: Leading the Way in Professional Mold Removal